Machining Infrastructure

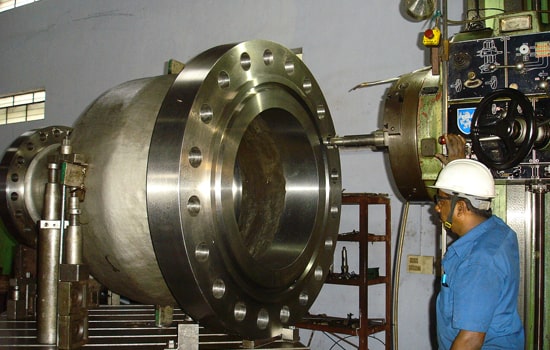

A One stop shop from raw material to machined components & assemblies, comprising of machining from light to heavy duty machine’s to perform basic operation like turning, milling, boring & drilling to complex profile milling & critical precision operation. Being handled by professional & dedicated workforce in synergy between man machine & method.

Over 40 + heavy CNC & Conventional metal working machinery under power.

Maximum capacity of machines:-

Turning:-

| S.NO | MACHINE TYPE | CHUCK SIZE | SWING | HEIGHT | MAX LOAD IN KG |

|---|---|---|---|---|---|

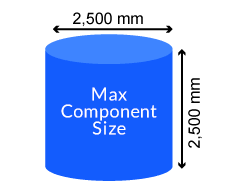

| 1 | CNC VTL | 2500 | 2650 | 2500 | 12000 |

| 2 | Conventional VTL | 2800 | 3000 | 2700 | 10000 |

Milling / Boring / Drilling:-

| S.NO | MACHINE TYPE | X | Y | Z | TABLE SIZE | MAX LOAD IN KG |

|---|---|---|---|---|---|---|

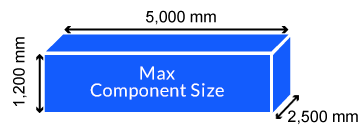

| 1 | VMC/Double Column Machining Center | 5000 | 2500 | 1100 | 5000 x 2500 | 12000 |

| 2 | Horizontal Machining Centers | 1900 | 1400 | 600 | 1000 x 1000 | 3000 |

| 3 | CNC Horizontal Boring Centers | 3000 | 2000 | 1000 | 1900 x 1900 | 12000 |

| 4 | Horizontal Boring Machines | 4000 | 2000 | 1000 | 1600 x 1600 | 10000 |

Fabrications

High precision industry has facility to manufacture fabricated parts upto 10 tons in weight. Having wide experience in making of fabrications using modern welding technologies. From simpler structure to critical functioning parts for locomotive engines.

CMM & Instruments

Coordinate Measurement Machines (CMM) are indispensable tools for ensuring the dimensional accuracy of precision manufactured products. While most manufacturers and metrology service providers are able to accommodate small and medium sized parts, very few have the CMM capability for larger sized parts.

Room-size CMM’s can accommodate very large parts, and can measure to micron-level resolution across 1-5 metres. High Precision Industry has the capability to accommodate parts up to 5 meter long. Large, high precision parts acclimated sufficiently to the temperature inside the CMM room before they can be mounted onto the measuring equipment.

| X axis | 2,500 mm |

| Y axis | 5,000 mm |

| Z axis | 1,800 mm |

| Measuring Resolution | 0.1 µm |

| Maximum job weight measurealbe | upto 15,000 kg |

Manufacturing solution & Exports

High Precision Industry has experienced supplier base for raw materials, castings, forgings , Metal heat treatments , Metal finishing etc. High Precision industry exports machined parts of weight up to 6 tons in single part weight. Our expertise & knowledge in supply of parts to various countries include USA , Canada , UK , Europe , and Asian countries.

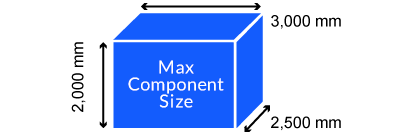

Capabilities

High precision Industry has wide range of Heavy Conventional machining to precision CNC machines suitable for small to heavy precision components. High Precision Industry has over 2,50,000 man / machine hours of capacity per year and with constant focus on infrastructure and facility development HPI adds CNC machines every year.

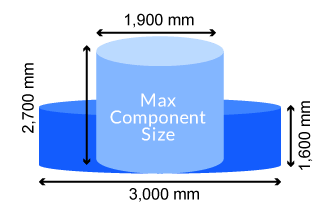

| S.NO | Machine Type | MAXIMUM SIZE OF COMPOENT CAN BE LOADED ON MACHINE | Max weight |

|---|---|---|---|

| 1 | Conventional Vertical Turning Lathe |  |

10,000 Kg |

| 2 | CNC Vertical Turning Machine |  |

12,000 Kg |

| 3 | CNC VERTICAL MILLING CENTERS |  |

12,000 Kg |

| 4 | CNC HORIZONTAL MILLING AND BORING CENTERS |  |

12,000 Kg |

Inhouse CAD - CAM facility for machining & manufacturing of Aerospace parts & 3D machining

Materials used for making parts

High precision industry performs machining & manufacture metal components from various material grades and compositions according to customers application & requirements . Below grades are commonly processed at our

| S.NO | RAW STOCK / PLATES / PIPES / TUBES / BLOCKS | Indian Standards, EU , ASTM |

|---|---|---|

| 1 | CASTINGS | WCB,WCCC,WC6,WC9,CF3,CF3M,CF8, C12A , 4A,5A CD4MN, CD3MN, High chromium steels Iron castings, grey iron etc. |

| 2 | FORGINGS | Steel forging, Aluminum Forgings & Alloyed forgings |